- Product

- Process Solutions

- HOME > Products > Process Solutions

- Grinding Process Equipment

- Classifiers & Separators

- Process Solutions

- Cryogenic Grinders

- Laboratory Equipment

- Tel

- 400-820-6150

Air Classification Process Line

Description:the process line consists of a classifier, cyclone powder collector and a fan/blower. The feed materials are pushed into the classification zone by the updraft created from the blowers, where the materials are separated through the centrifugal forces created by the turbine as according to the requirements set by the user. Only material that meets the particle size requirements passes through the screens to be collected by the cyclone powder collector, while the coarser materials are returned into the grinding zone for further size reduction.

Classifier Features:

●Suitable for classifying dry fine powders in shapes such as scales, spheres, flakes, needle-like particles, and also based on different densities.

●Product size grading up to diameters 2 - 150 microns particle size, with extremely convenient material replacement features.

●High classification efficiency (extraction rate) of 60% to 90%.

●Vertically mounted turbine unit, featuring low speed, high wear resistance and low system power consumption.

●Multi-level classifier can be used in tandem, while the production of multiple products segment size.

●Compatible with ball mills, vibration mills, Raymond mills and other equipment to form a closed system.

●The control system uses a process control system with real-time operating status display for easy operation.

●Clean and silent system operation with dust emissions not more than 40mg / m³, and noise level no higher than 75dB(A) (with a silencer).

FFL Series Air Classifier Technical Parameters

|

Parameters/ Model

|

FFL200

|

FFL300

|

FFL450

|

FFL550

|

FFL630

|

FFL800

|

FFL1000

|

|

Capacity kg/h

|

20~200

|

200~1000

|

1000~3000

|

3000~5000

|

8000~15000

|

15000~20000

|

20000~30000

|

|

Output Diameter: um

|

5~150

|

6~150

|

8~150

|

10~150

|

|

|

|

|

Classification Efficiency %

|

60~90

|

60~90

|

60~90

|

60~90

|

60~90

|

60~90

|

60~90

|

|

Power kw

|

8.5~25

|

11.5~42.5

|

63.5~105

|

77~120

|

120~160

|

90~200

|

170~310

|

Note: The size, specific gravity, moisture, and other indicators of liquidity and raw material production rates above are for reference selection only.

FFW Series Classifier Technical Parameters

Multi-rotor classifier

|

Parameters/ Model

|

FFW400/3

|

FFW400/4

|

FFW400/6

|

FFW630/3

|

FFW630/4

|

FFW630/6

|

FFW800/3

|

FFW800/4

|

FFW800/6

|

|

Capacity T/h

|

0.2~1.5

|

0.3~2

|

0.5~3

|

1~5

|

2~8

|

3~10

|

2~8

|

3~10

|

5~15

|

|

Output Diameter:um

|

2~45

|

2~45

|

3~45

|

3~45

|

3~45

|

3~45

|

4~45

|

4~45

|

4~45

|

|

Classification Efficiency %

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

|

Power kw

|

90-110

|

120-140

|

170-200

|

135-155

|

170-190

|

250-290

|

180-200

|

220-290

|

290-390

|

Note: The size, specific gravity, moisture, and other indicators of liquidity and raw material production rate are for reference selection only.

Single Rotor Classifier

Applications:Widely used in chemical, minerals (especially for calcium carbonate, kaolin, silica, talc, mica and other non-mineral grade), metallurgy, abrasives, ceramics, refractories, pharmaceuticals, pesticides, food, health products, new materials and other industries.

Air crushing and grading system applications:

FQW series jet milling full production line

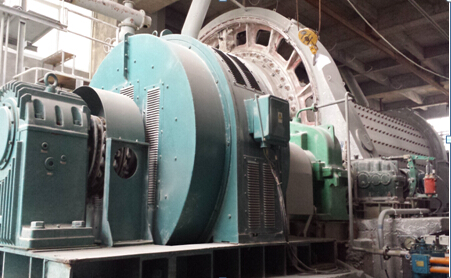

Ball milling and classifying production line

Ball milling and classifying production line